The FlexiFlow Expand Gate is an advanced environmental flow-control solution designed to protect lakes, rivers, and downstream ecosystems from untreated sewage discharge during heavy rainfall and peak inflow conditions. Manufactured and installed by Floecksmühle Energietechnik GmbH, FlexiFlow is in operation worldwide and provides municipalities with a reliable way to manage combined sewer system overloads while maintaining public safety and regulatory compliance.

In combined sewer systems, rainwater and wastewater are conveyed together to treatment facilities. During intense storm events, inflow can exceed both the collector duct and treatment plant capacity. Without flow regulation, excess sewage may be discharged into nearby waterways. FlexiFlow addresses this issue by transforming existing sewer pipes into temporary in-pipe storage reservoirs.

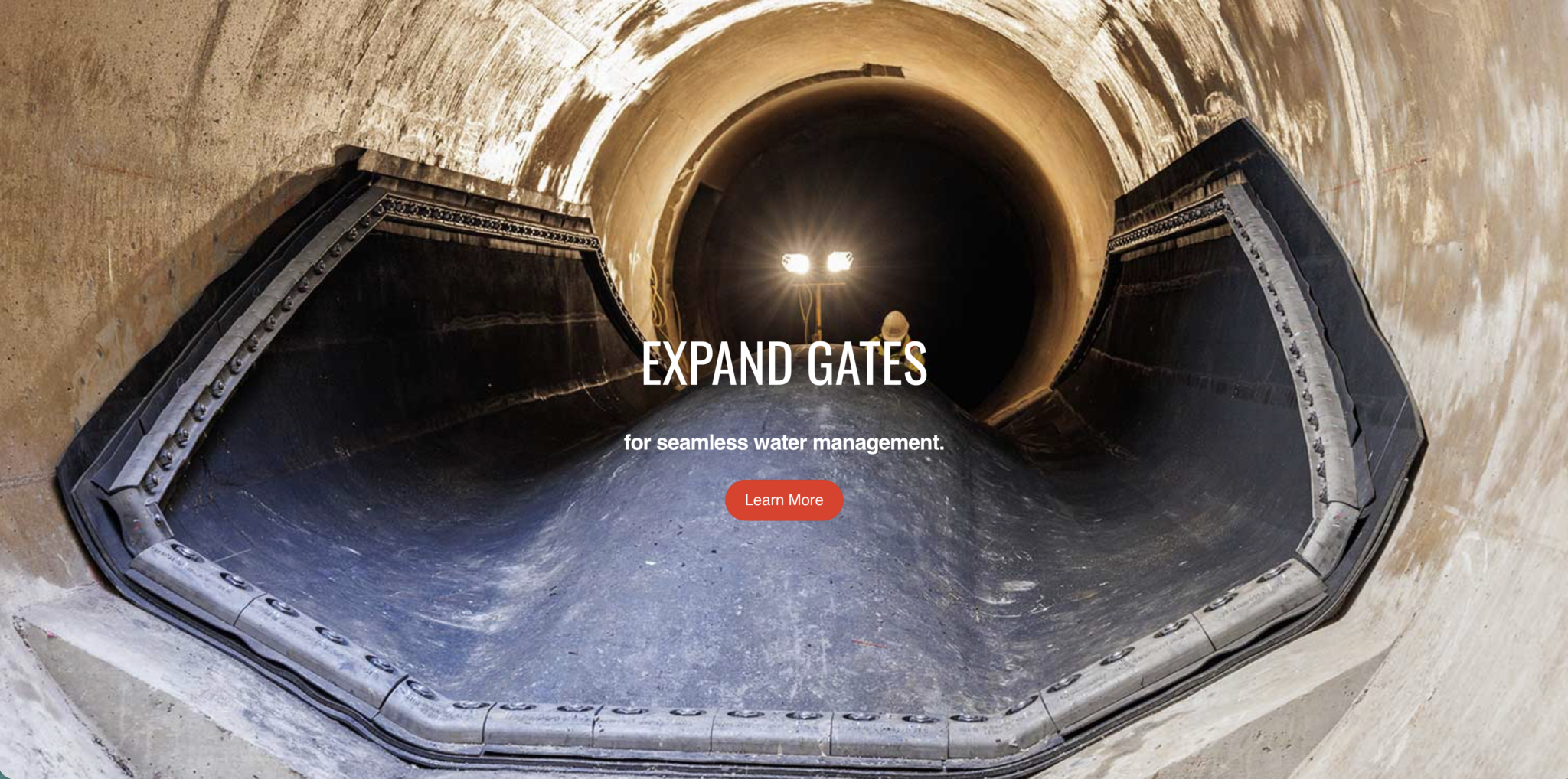

The system utilizes an air-filled, high-durability rubber bladder that expands within the pipe to partially restrict or completely shut off flow as needed. By regulating discharge rates, FlexiFlow ensures that treatment plants are not overwhelmed during peak inflow events. Once capacity stabilizes, the gate deflates and normal flow resumes.

Before installation, system capacity, tunnel profile, hydraulic conditions, and control integration requirements are evaluated to ensure optimal performance. FlexiFlow can be retrofitted into existing systems and installed through manholes, minimizing excavation and disruption to the public.

Municipalities and wastewater authorities often select FlexiFlow because it provides environmental protection while maintaining infrastructure reliability. Some of the reasons to choose FlexiFlow include, but are not limited to:

Environmental protection. Prevents untreated sewage discharge into lakes and rivers during storm events.

In-pipe storage utilization. Converts existing sewer infrastructure into temporary storage reservoirs without large-scale construction.

Retrofittable design. Can be installed in existing pipes through manholes, significantly reducing surface disruption.

Fail-safe operation. Designed with a deflated default state and manual valve control during power outages.

Low maintenance. Corrosion-resistant construction with no mechanical moving parts; typically requires only annual cleaning.

SCADA compatibility. Fully compatible with modern control and monitoring systems for precise regulation.

Long operational life. High resistance to wear and abrasion ensures durability in demanding sewer environments.

All FlexiFlow systems are engineered for safety, reliability, and long-term municipal use. Regulation and control systems are manufactured in the USA or EU, and the bladder material is specifically designed for abrasion resistance and corrosion durability in combined sewer applications.

Generally speaking, a properly specified FlexiFlow Expand Gate is designed to match the lifespan expectations of the sewer infrastructure itself. Service life is influenced by factors such as abrasion levels, flow frequency, chemical exposure, system pressures, and overall operational conditions. These considerations are evaluated during the design and specification phase to ensure long-term performance.

FlexiFlow can accommodate a wide range of tunnel and pipe configurations, including:

Round pipes

Arched tunnels

Square profiles

Rectangular profiles

Rounded cross-sections can be completely sealed off when required.

Size Range:

Minimum duct diameter: 5 ft (1.5 m)

Maximum duct diameter: 15.5 ft (4.72 m)

Bladder height range: 3.5 ft (1.05 m) to 14 ft (4.27 m)

Concrete pad height: 1.5 ft (0.45 m)

This flexibility allows FlexiFlow to be integrated into a wide variety of municipal sewer systems and tunnel structures.

Kevlar®-reinforced liner withstands high pressures and restores structural integrity.

Installs through existing manholes and adapts to round, arched, square, and rectangular tunnel profiles with minimal system modification.

Transforms current sewer pipes into temporary in-pipe storage reservoirs—eliminating the need for major excavation or new construction.

Designed with a deflated default state for safety and integrates seamlessly with SCADA systems for precise monitoring and flow control.

FlexiFlow is an expandable in-pipe flow-control gate that regulates sewage flow during heavy rainfall to prevent untreated discharge into waterways.

By temporarily storing excess inflow within existing sewer pipes, FlexiFlow prevents combined sewer overflows from reaching lakes and rivers.

Yes. It can be retrofitted into existing pipes and installed through manholes, minimizing excavation and surface disruption.

FlexiFlow is designed with a fail-safe deflated default state and includes a manual valve for controlled deflation during outages.

Round, arched, square, and rectangular tunnel profiles.

FlexiFlow can be installed in pipes ranging from 5 ft to 15.5 ft in diameter, depending on system design.

Yes. The gate operates with a SCADA-compatible control system for precise monitoring and regulation.

The system has no moving mechanical parts and typically requires only annual cleaning.

The gate uses a high-durability, air-filled rubber bladder designed for wear resistance and corrosion protection.

Municipalities and wastewater authorities operating combined sewer systems that experience peak inflow or overflow challenges during heavy rainfall events.